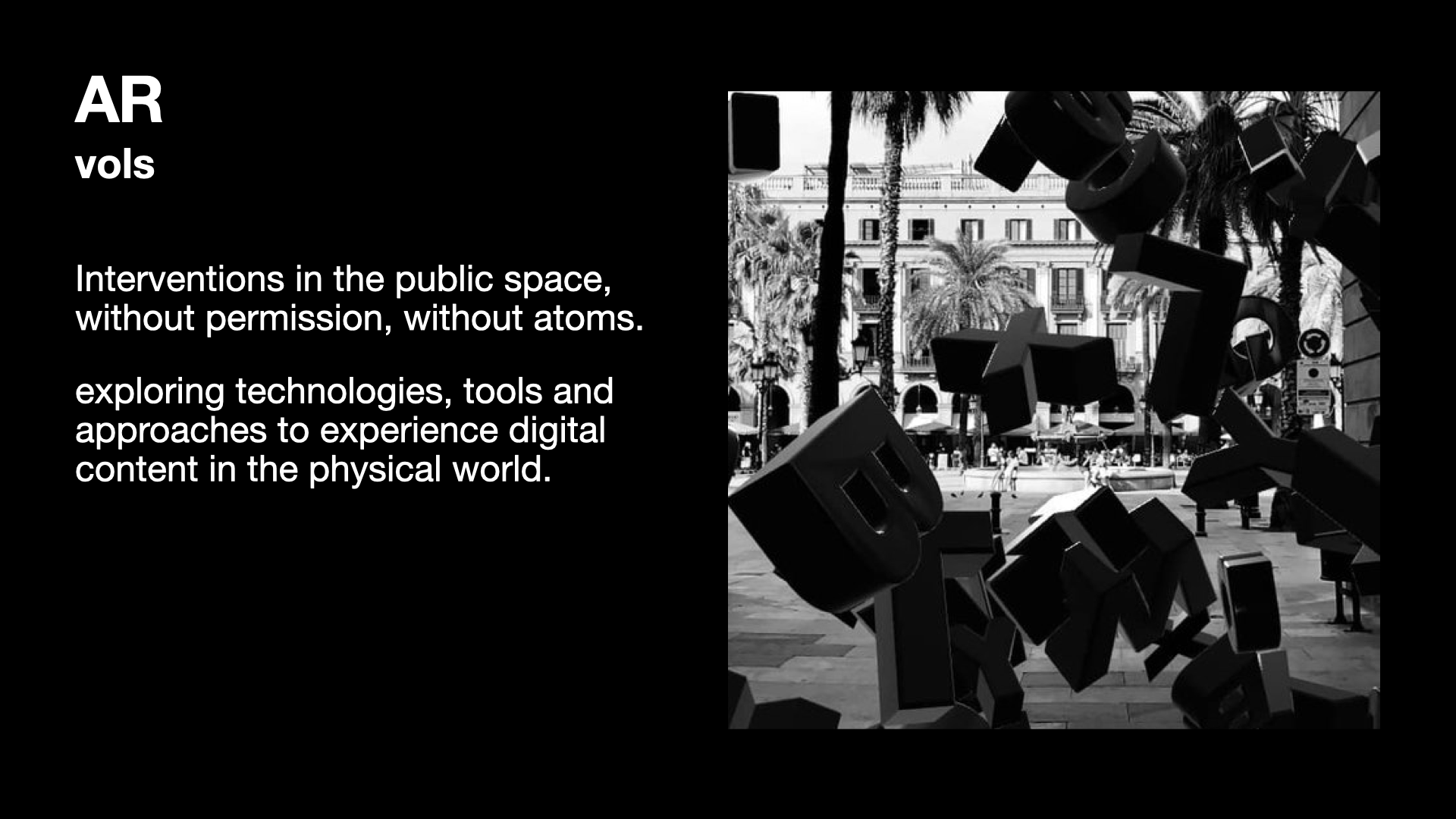

new media works

When there is a new way of making things,

there is a new way to design them.

This is what we do:

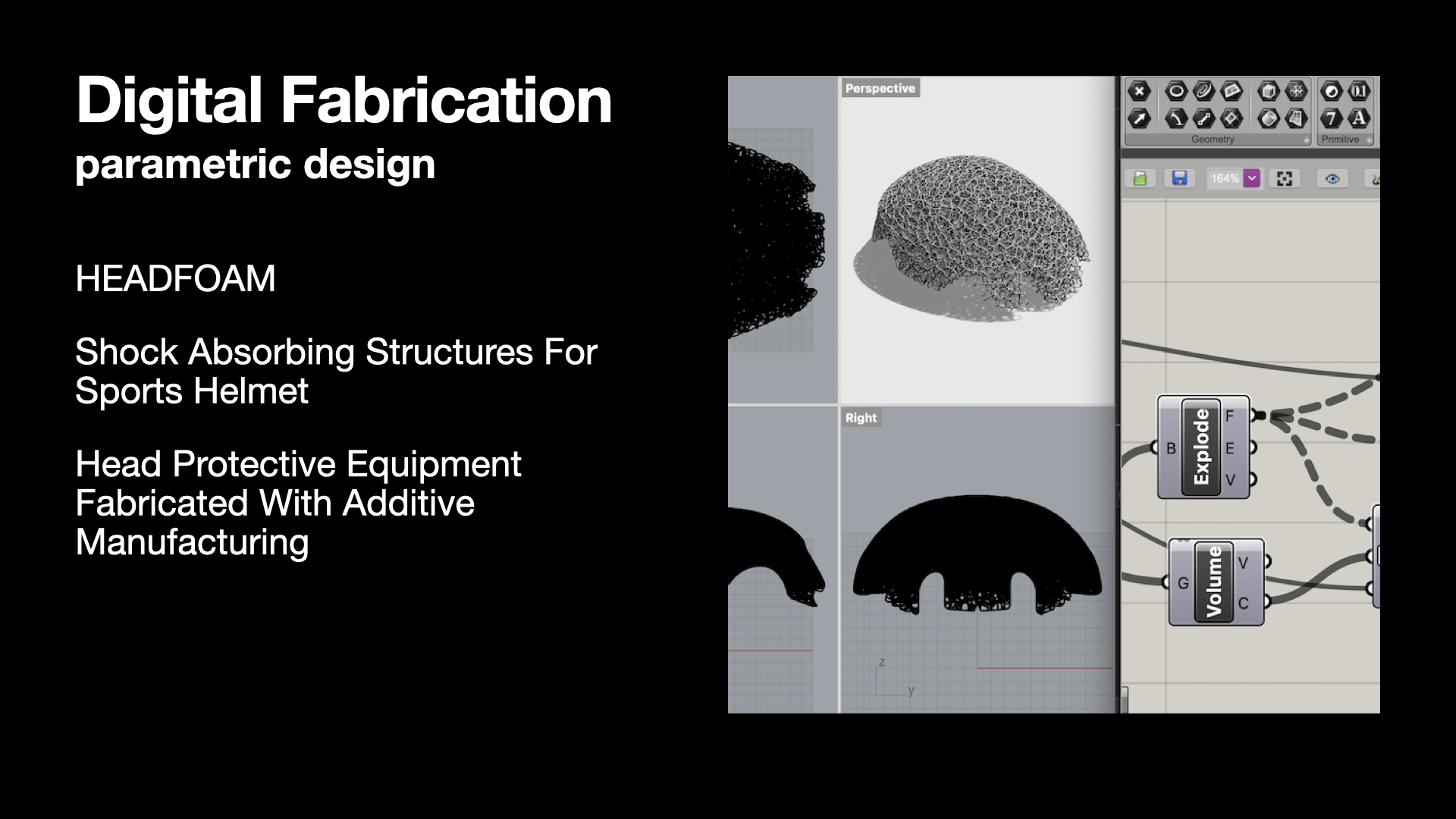

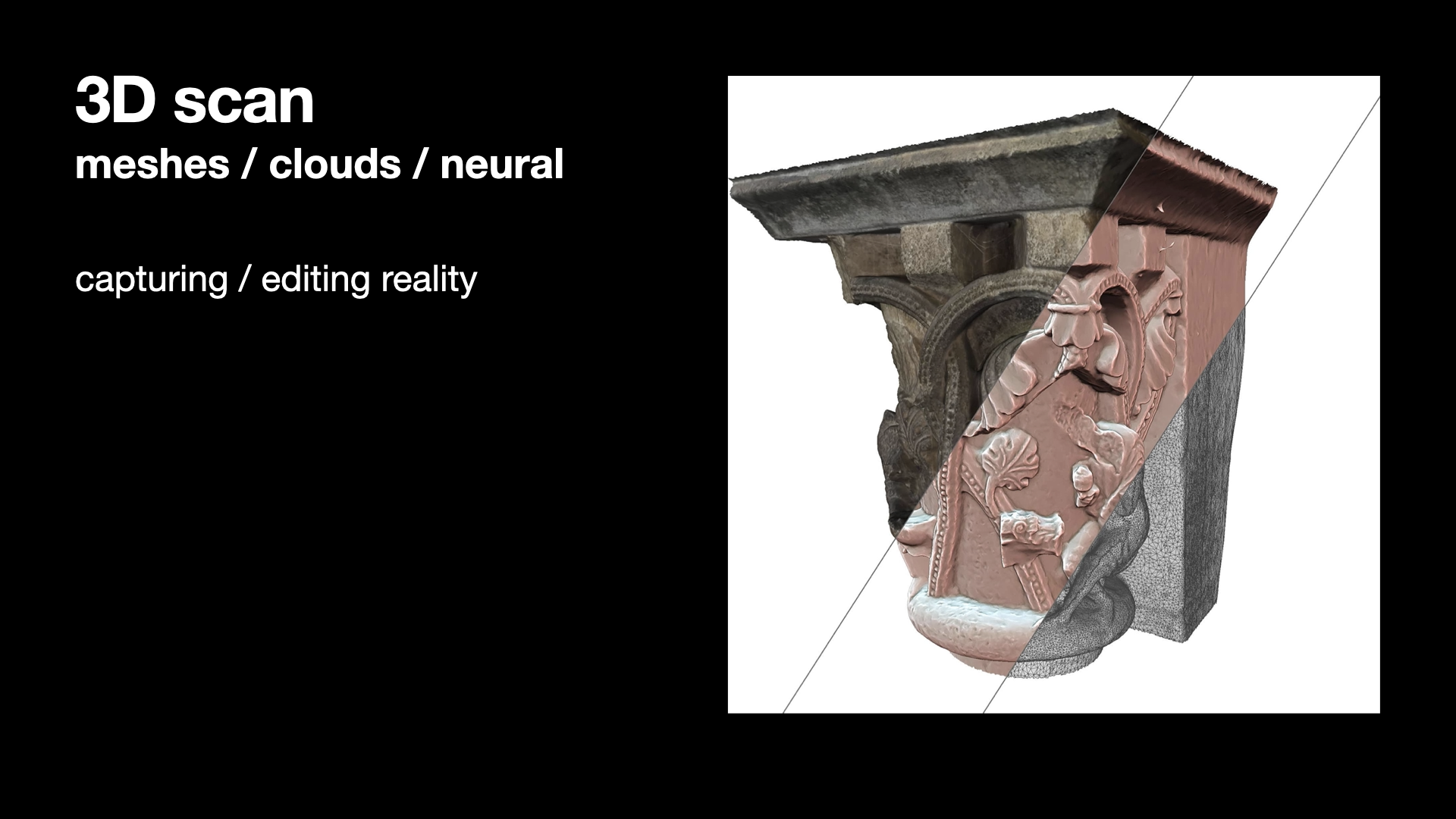

Research the new aesthetics of additive manufacturing

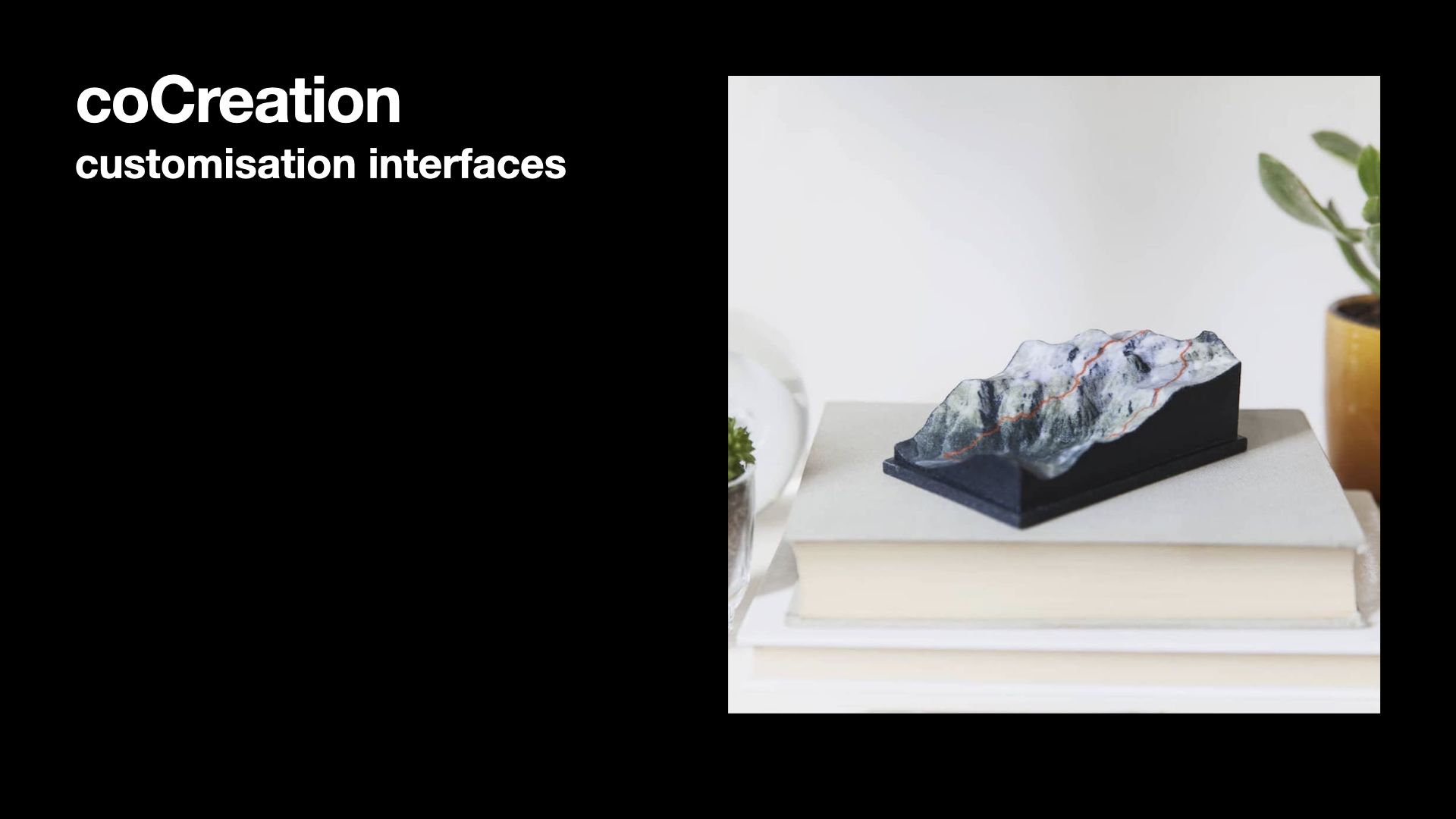

Explore business opportunities for the maker economy

Make design tools for everyone

Make & Sell products using the digital fabrication ecosystem

We believe in the popularization of design tools & processes to lower the entry barriers to the world of making things.

Exploring scenarios of creation, production and consumption through design, digital fabrication & 3D Printing.

Team

Mainly run as a one-man shop by Bernat Cuni, a product designer specialized in digital fabrication with experience in the fields of design research, eco-design and design entrepreneurship.

Cunicode collaborates with expert individuals, and service providers to build a perfect team for each project.

A growing network of local and international technological centers and production hubs enable cunicode to deliver production through digital fabrication.

*...I'm looking for great coders. If you master webGL, javascript, 3D and want to help cunicode make awesome apps that make things, please contact.

Design & 3D Printing | talk [es] at DHUB the Design Museum Barcelona

About 3D Printing

Thoughts on Digital Fabrication

Talk at the Additive Manufacturing Forum | Barcelona 2011

Glossary

Video sponsored by DHUB (Disseny Hub Barcelona) & created by nueveojos illustrates a possible future where 3D-Printing becomes mainstream and products are made on demand.

FabLab

Fabrication Laboratory

Is a small-scale workshop offering digital fabrication. It is generally equipped with an array of flexible computer controlled tools that cover several different length scales and various materials, with the aim to make “almost anything”. This includes technology-enabled products generally perceived as limited to mass production.

Fab Central The Fab Lab program is part of the MIT’s Center for Bits and Atoms (CBA) which broadly explores how the content of information relates to its physical representation.

Consumer 3D Printing

Several projects and companies are making efforts to develop affordable 3D printers for home desktop use. Much of this work has been driven by and targeted at DIY/enthusiast/early adopter communities, with additional ties to the academic and hacker communities.

SLA Stereolithography

Stereolithography is an additive manufacturing process using a vat of liquid UV-curable photopolymer “resin” and a UV laser to build parts a layer at a time. (+Wikipedia)

SLS Selective Laser Sintering

Selective laser sintering uses lasers as its power source to sinter powdered material, binding it together to create a solid structure. It is often confused with selective laser melting (SLM), the difference being that SLS only sinters the powders together as opposed to achieving a full melt.

Open Hardware

Open source hardware consists of physical artifacts of technology designed and offered by the open design movement. Both free and open source software (FOSS) as well as open source hardware is created by this open source culture movement and applies a like concept to a variety of components. The term usually means that information about the hardware is easily discerned.